Dockwise yacht transport express vessel

Intervention type

CommissioningLocation

Rotterdam, NetherlandsApplication description

This Yacht Transport Vessel is the largest of its kind, and it has a variety of unique features. The vessel is semi-submersible and offers a unique float-on/float-off loading method. It has a length of 209 meters (685.7 ft) and a deck space of 5,115 square meters (55,060 ft).

There were multiple challenges in the installation, combining MV and LV busbar, electric propulsion, thrusters and ballasts control with heavy consumers water pumps and yet to give absolute power control during the deballasting and ballasting of the ship when loading the expensive vessels. The deballasting was the most difficult stage of the operation since the Yachts have different sizes and drafts and have to lie down carefully on wooden cribbing. At this particular stage, the trim of the boat has to be perfectly balanced. GENSYS 2.0 MARINE was chosen for its flexibility and ability to handle this highly complex application. This application requires hundreds of additional Inputs/Outputs, which are managed by the PLC programming embedded into GENSYS 2.0 MARINE.

Our solution

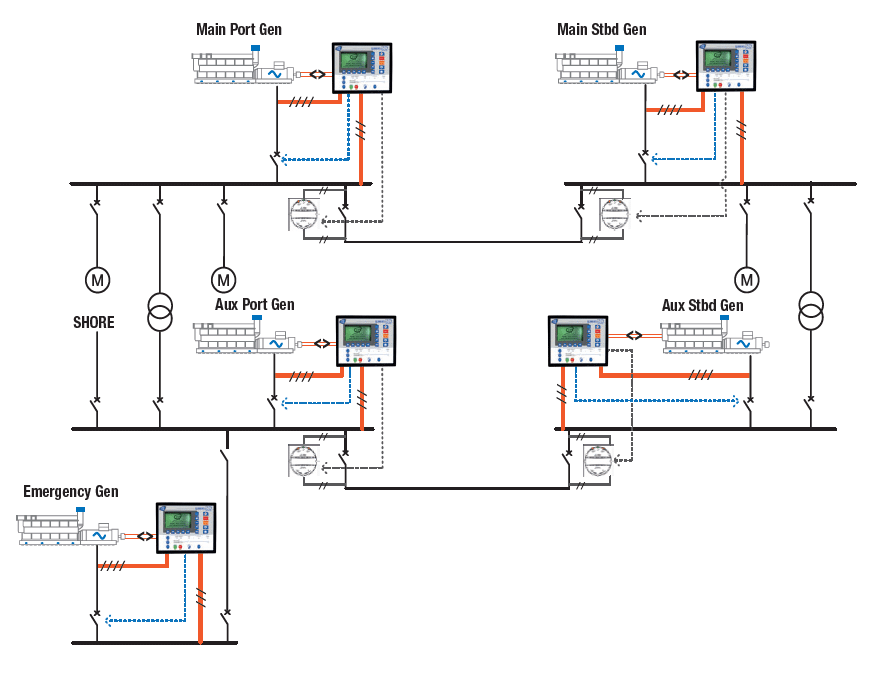

This vessel has electric propulsion, and the power plant consists of 2 Wärtsilä 12V38 B 8700KW diesel generators. The 2 generators are controlled on island/paralleling mode by GENSYS 2.0 MARINE system. The generators are mainly dedicated to the control of 2 thrusters via 2 electric engines of 5100 kW each.

The GENSYS 2.0 MARINE system is doing more than synchronising and load sharing the medium voltage power plant, it is controlling and synchronising the tie breakers separating the starboard bus and the port bus, and it is also managing the propulsion limitation through CANopen remote analog inputs. Auxiliary power is derived from 2 Wärtsilä common rail diesel gensets of 1,020 kW managed by 2 GENSYS 2.0 MARINE with synchronization, load sharing and dedrooping mode.

Backup power is provided by a Volvo Penta D34A MS 610 kW, 440 V, 60 Hz diesel generator, always controlled by the GENSYS 2.0 MARINE. Each power unit can be isolated for maintenance operations, and can be synchronized back without blackout thanks to the GENSYS 2.0 MARINE's « tie breaker » synchronization function.

The shore power failure is also check by GENSYS 2.0 MARINE and causes the 2 auxiliary generators for black start operation.

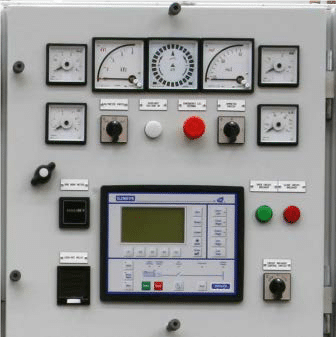

Products installed

- GENSYS 2.0

Application diagram